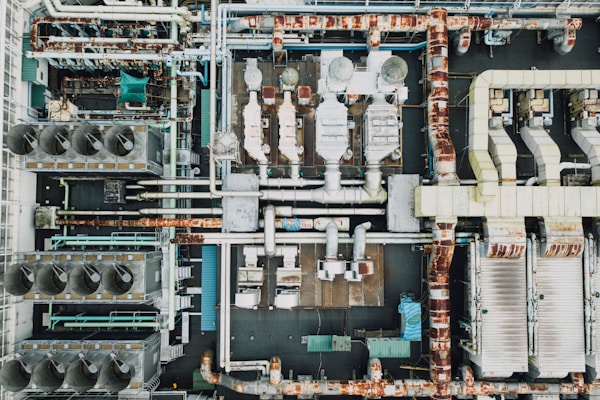

Screw compressors are a vital part of industrial ammonia refrigeration systems. They are used to heat vaporized refrigerant and increase its pressure so it can move throughout the entire system quickly and easily after being cooled down by the condenser. The screw compressor is a type of positive displacement compressor which works by trapping a fixed amount of gas and compressing it. This compressor is efficient and reliable, making it a popular choice for industrial applications. Keep reading to learn more.

What are industrial screw compressors?

Screw compressors have been used in industrial refrigeration systems for years and are becoming increasingly popular. They are ideal for applications where a high-pressure refrigerant is required. They are also more efficient than other types of compressors, consuming less energy and reducing the cost of energy bills.

Screw compressors are designed to work at high pressures, which allows for efficient cooling of larger volumes and systems. They also produce a constant stream of refrigerant and air, which is important for the consistency of temperature and humidity control. These types of compressors are an essential part of keeping a precise temperature in product inventories, as they can produce the necessary refrigerant more efficiently. This ensures that the products are stored safely and at the optimal temperature, reducing spoilage and wastage.

In addition, these compressors are highly efficient because they maintain a steady flow rate without any pulsations or surges. They have high volumetric efficiency, meaning they can accurately and efficiently compress gas without wasting energy. This makes them an excellent choice for applications where energy consumption is a significant concern. Additionally, the screw compressor can easily handle large loads, which can be beneficial for industrial applications.

Screw compressors are low-maintenance, cost-effective, and highly efficient, making them an excellent choice in industrial applications for maintaining precise temperatures in product inventories.

What are the benefits of using screw compressors?

A significant advantage of screw compressors is their ability to attain high-pressure ratios in a single mode. This allows large volumes of refrigerant to be compressed without needing a double-stage unit. This is especially beneficial in refrigeration and liquefaction applications, making them a preferred choice.

Screw compressors are also known for their reliability and ease of maintenance. They have fewer moving parts than other compressors and do not require frequent oil changes or service tasks. In addition, the mechanical efficiency of screw compressors is typically higher than those of reciprocating compressors and usually has a longer service life. This makes them an excellent choice for applications that require long-term reliability.

Screw compressors can also handle high temperatures and pressures, making them well-suited for applications requiring high-pressure ratios and extreme temperatures. This compressor is ideal for applications that involve critical processes, such as those in industrial settings.

Unlike reciprocating compressors, which have moving parts that are subject to wear and tear, the rotors of screw compressors turn at conservative speeds that minimize wear and tear, making these compressors perfect for demanding applications such as large-scale industrial systems. Furthermore, the rotors of screw compressors are well lubricated with coolant oil, which helps keep them running smoothly. The lubrication also helps reduce wear and tear on the rotors, extending the compressor’s life, while the oil also helps keep the compressor cool, preventing overheating and potential damage.

A well-designed screw refrigeration compressor is one of the most efficient and reliable industrial compressors available today. By providing high levels of efficiency, low noise levels, and easy maintenance, they are ideal for a wide range of applications. With the right design, a screw compressor can provide years of reliable performance and cost savings.